Knowing how to use a metal lathe can be an essential skill for anyone involved in metalworking.

In this guide, we blow the dust off our lathe to walk you through the process of using a metal lathe, from setting up the machine to performing various cutting operations.

Let’s dive right in and start learning!

What Is A Metal Lathe

First off, let’s take a look at what exactly a metal lathe is and how it compares to a non-metal lathe.

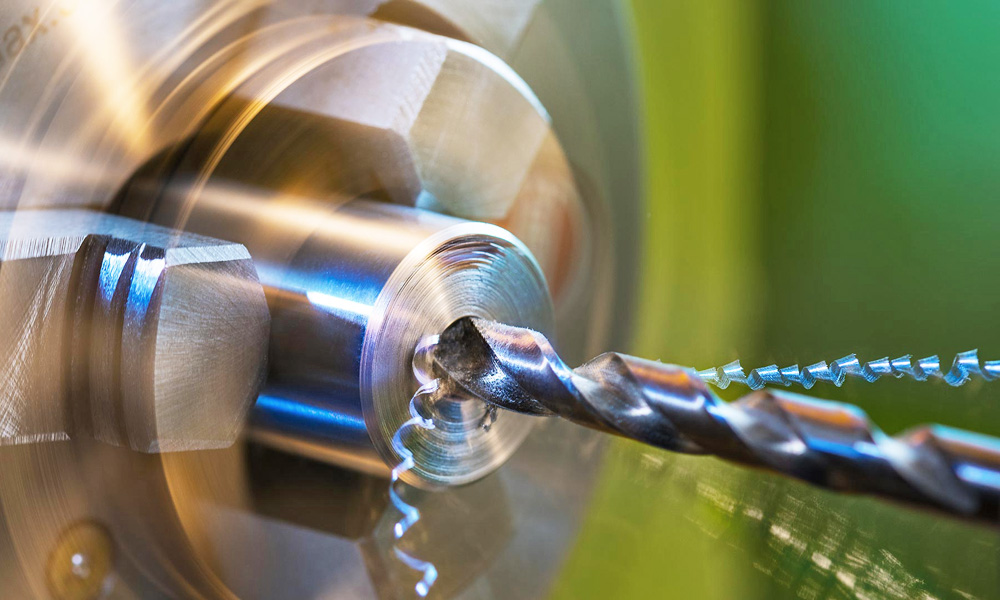

A metal lathe is a machine tool that is used to shape and turn metal workpieces. It operates by rotating the workpiece against a cutting tool, allowing for precision shaping and machining of various metal materials.

Metal lathes are specifically designed to handle the unique properties and demands of working with metals, such as steel, iron, brass, and aluminum. They are built with heavy-duty components and have higher horsepower capabilities to withstand the rigors of metalworking.

In contrast, non-metal lathes are generally used for working with softer materials like wood or plastic. While they may share some similarities in terms of basic operation, their construction and capabilities differ significantly. Metal lathes offer greater power, rigidity, and precision to handle the challenges of working with metal.

Metal Lathe Components

Now that we have a good understanding of what a metal lathe is, it’s time to drill (no pun intended) into its various components.

The main parts of a metal lathe include the bed, headstock, tailstock, carriage, tool post, and chuck.

- The bed is the foundation of the lathe and provides support for all the other components.

- The headstock contains the motor and gears that drive the spindle, which holds the workpiece.

- The tailstock can be moved along the bed to support longer workpieces and also houses a center for additional support.

- The carriage moves along the bed and holds the cutting tools, allowing them to engage with the workpiece.

- The tool post securely holds the cutting tools and allows for quick and easy tool changes.

- The chuck is used to hold and rotate the workpiece during machining operations.

Having a thorough understanding of these metal lathe components is essential before hitting that power switch.

Different Types of Metal Lathes

Within the metalworking field, there are more lathe variations than you would think, each serving different purposes and catering to specific needs. While some variations may be more commonly known, others exist in more niche areas of metalworking. Each variation has its own unique features and capabilities, allowing metalworkers to perform a wide range of tasks with precision and efficiency.

Here are the most common types of metal lathes you will find, each with its own unique features and capabilities:

- Center Lathe

- Engine Lathe

- Bench Lathe

- Toolroom Lathe

- Turret Lathe

- Capstan Lathe

- Automatic Lathe

- CNC Lathe

Now that you know the most common types of metal lathes, let’s dive into what we all came here for – how to use a metal lathe!

How To Use A Metal Lathe

Using a metal lathe isn’t rocket science, but it does require precision, patience, and a steady hand. With the right steps (and some common sense safety), you can turn raw stock into smooth, professional pieces.

So, grab your safety goggles and let’s get spinning.

1. Suit Up

Safety first, always. Lathes spin at thousands of RPM, and you don’t want anything extra spinning with it.

- Wear safety glasses (a must).

- Toss on hearing protection — lathes can hit 85–100 dB, which is about as loud as a chainsaw.

- Skip the loose clothes and jewelry.

- A shop apron and high-neck shirt help protect against flying chips.

2. Warm It Up

Before you touch any stock, give the machine a quick warm-up.

- Set the spindle to ~1000 RPM.

- Let it run for about 10 minutes.

- Check lubrication while it’s spinning — friction is your enemy here.

Pro tip: Use this time to set up your tooling so you’re not scrambling later.

3. Load the Stock

How you mount the metal depends on your project:

- Chuck → Your everyday, go-to grip.

- Collet → Best for small, precise work.

- Faceplate → Handles big or weird shapes.

- Mandrel → Perfect for hollow cylinders.

- Center/Drive plate → Keeps long pieces steady.

Whatever you use, double-check it’s lined up and locked in tight. A loose stock can ruin both your part and your day.

4. Check the Clearance

Before firing it up, give the stock a manual spin. If you hear scraping, see wobbling, or feel resistance — stop and fix it.

One bad alignment = wasted material and a possible accident.

5. Pick Your Tools

Different jobs, different tools:

- Tailstock tools → drilling, tapping.

- Parallel tools → chamfering, turning, tapering.

Keep your tools sharp — dull cutters create heat, strain the machine, and give you a messy finish.

6. Make Your Marks

Grab a permanent marker (or layout dye if you’re fancy). Mark your cuts, tapers, or drilling points. These won’t smudge easily and will keep you on track.

Think of it as a road map for your machining.

7. Adjust the Tool Rest

Slide the tool rest into position, then make sure it’s got a bit of clearance from the stock. Do a quick check by gently “springing” the piece — no contact means you’re good to go.

8. Start Cutting

Now the fun part.

- Set your spindle speed.

- Place your tool on the rest.

- Ease it into the spinning stock slowly.

Don’t rush — smoother, lighter passes give you better results than forcing it.

9. Stop & Check

After a few passes, stop the lathe completely and check your work:

- Look for irregularities.

- Measure dimensions with calipers.

- Adjust alignment if needed.

Pro tip: Breaks aren’t just for coffee — they save material and catch mistakes early.

10. Finishing Touches

For a cleaner finish, use cutting fluid. It helps:

- Reduce heat buildup.

- Prevent rust.

- Clear away chips.

- Extend tool life.

- Leave a smoother surface.

11. Clean It Up

Don’t leave chips and coolant sitting around. After each use:

- Brush or vacuum big debris.

- Wipe surfaces with a mild cleaner.

- Dry everything completely to avoid rust.

A clean lathe is a happy lathe.

12. Maintain Your Machine

Regular upkeep keeps your lathe running for years.

- Keep tools sharp.

- Lubricate the headstock bearings.

- Check and refill oil reservoirs.

Do these before every session and you’ll avoid most headaches down the road.

Practice & Patience

Knowing how to use a metal lathe can be a rewarding experience for those with a passion for craftsmanship. It requires precision, skill, and attention to detail, but with practice and patience, you can quickly become an expert machinist.