If you’ve ever struggled to drill a clean hole through thick metal, you know the frustration of smoking drill bits, misaligned holes, and endless finishing work. Traditional drilling can be slow, inefficient, and tough on your tools. That’s where annular cutters come in.

This guide covers everything you need to know: what an annular cutter is, what it’s used for, how to use it, and tips for selecting and maintaining the right cutter. By the end, you’ll see why these tools are a must-have for professionals and DIYers alike.

What Is an Annular Cutter?

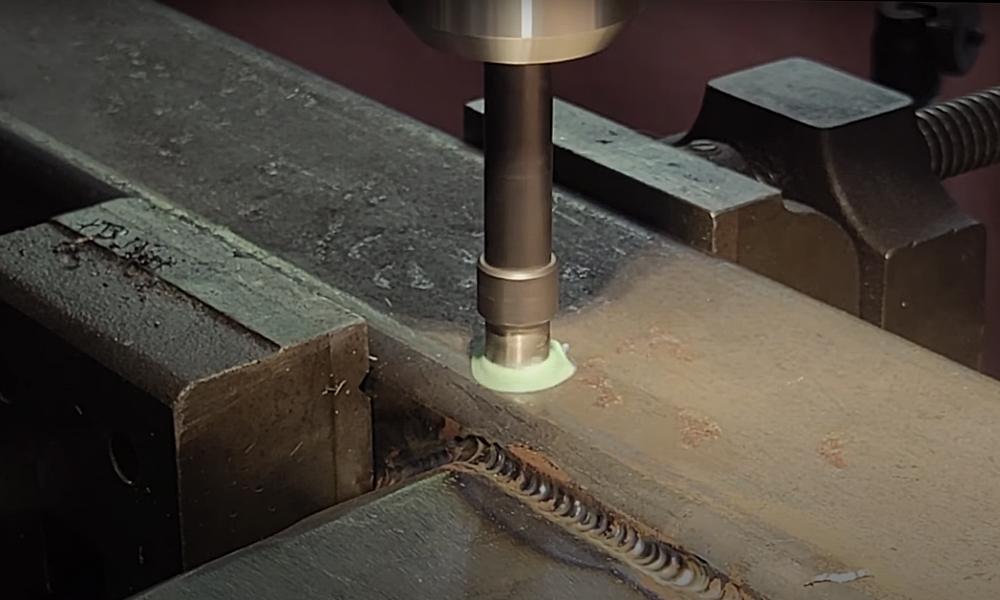

An annular cutter is a specialized metal-cutting tool designed to create precise, burr-free holes in thick metal. Unlike standard twist drill bits, which grind away the entire material in the hole’s path, annular cutters cut only the outer edge of the hole.

This design leaves a smooth, clean hole and a solid metal slug in the center. The cutter typically has cutting teeth along the edge and a pilot pin in the center to guide the tool and ensure accurate alignment.

Annular cutters are available in several materials:

- High-Speed Steel (HSS): Versatile and ideal for general metalworking.

- Carbide-Tipped Cutters: Tougher, more durable, and perfect for hard metals or extended tool life.

By cutting only the perimeter, annular cutters reduce heat and friction, speed up drilling, and produce more accurate holes than traditional methods. Pairing the cutter with a lubricant like Anchorlube further enhances performance, making the process smoother and extending tool life.

What Is an Annular Cutter Used For?

If you’re asking, “what is an annular cutter used for?”, the answer is simple: wherever you need clean, precise holes in thick metal. These tools shine in multiple industries:

- Structural Steel Fabrication: Perfect for drilling holes in I-beams, plates, and channels.

- Automotive and Machinery: Ideal for chassis modifications, repair work, and custom projects.

- Construction and Welding: Speeds up assembly and reduces post-drill finishing.

- Plumbing and HVAC: Makes clean penetrations in metal pipes and ductwork easy.

Annular cutters are especially useful for holes larger than 1/2 inch in diameter. Unlike twist drills that require multiple steps or pre-drilling, annular cutters create clean, round holes with minimal effort, eliminating ragged edges and reducing heat distortion.

How to Use an Annular Cutter

Learning how to use an annular cutter is straightforward if you follow a few best practices. Most cutters are designed for magnetic drills (mag drills), which stabilize the tool and ensure straight, precise cuts. Here’s a step-by-step guide:

- Secure the Cutter: Insert the annular cutter into the mag drill’s chuck or arbor. Ensure it’s tightly fastened.

- Apply Lubricant: Use a cutting fluid on the cutter teeth or the workpiece. This reduces friction and heat, making the cut faster and smoother.

- Set Depth and Location: Align the pilot pin with your mark and lower the cutter onto the metal.

- Feed the Cutter: Allow the annular cutter to feed itself. Avoid forcing it, as pressure can damage the tool or workpiece.

Pro Tip: You can use annular cutters in a drill press if it has sufficient torque and rigidity. Clamp the workpiece securely and proceed slowly to avoid misalignment or accidents.

Choosing the Right Annular Cutter

Selecting the right annular cutter ensures better performance and longer tool life. Here’s what to consider:

- Material: HSS cutters are great for general use, while carbide-tipped cutters handle tough metals and high-volume work.

- Diameter: Match the cutter size to your fastener or hole requirement. They’re best for holes larger than 1/2 inch.

- Shank Type: Ensure compatibility with your mag drill or drill press arbor.

Maintenance Tips: Proper care prolongs the life of your annular cutter. Use lubrication during cutting, avoid overheating, and store cutters safely. For worn cutters, professional sharpening services can restore performance without the cost of a new tool.

Advantages of Using an Annular Cutter

Switching to annular cutters offers clear benefits:

- Faster Drilling: Cuts only the perimeter, so less material is removed.

- Clean Holes: Produces burr-free holes with tight tolerances.

- Reduced Heat & Friction: Protects both tool and workpiece.

- Versatility: Works on mild steel, stainless steel, aluminum, and more.

For professionals and DIYers, these advantages mean less time, less effort, and more consistent results.

Final Thoughts: Drill Smarter, Not Harder

If you’re still relying on twist drill bits for large metal holes, it’s time to level up. Annular cutters provide faster, cleaner, and more precise results, reducing frustration and improving efficiency.

When combined with a mag drill and Anchorlube, annular cutters let you work with confidence, achieving professional-quality holes with minimal effort. Whether you’re tackling structural steel, automotive projects, or home metalworking, annular cutters are a must-have tool.

So grab your cutter, apply your lubricant, and let precision do the heavy lifting. With an annular cutter, you’re not just drilling – you’re cutting like a pro.