In most machine shops, processes evolve over time. A setup that worked great five years ago might still be “getting the job done” today – but that doesn’t always mean it’s running efficiently.

If you’re seeing small issues pile up, it may be time to step back and evaluate your machining process. Below are some common warning signs that a refresh – whether big or small – could improve quality, consistency, and profitability.

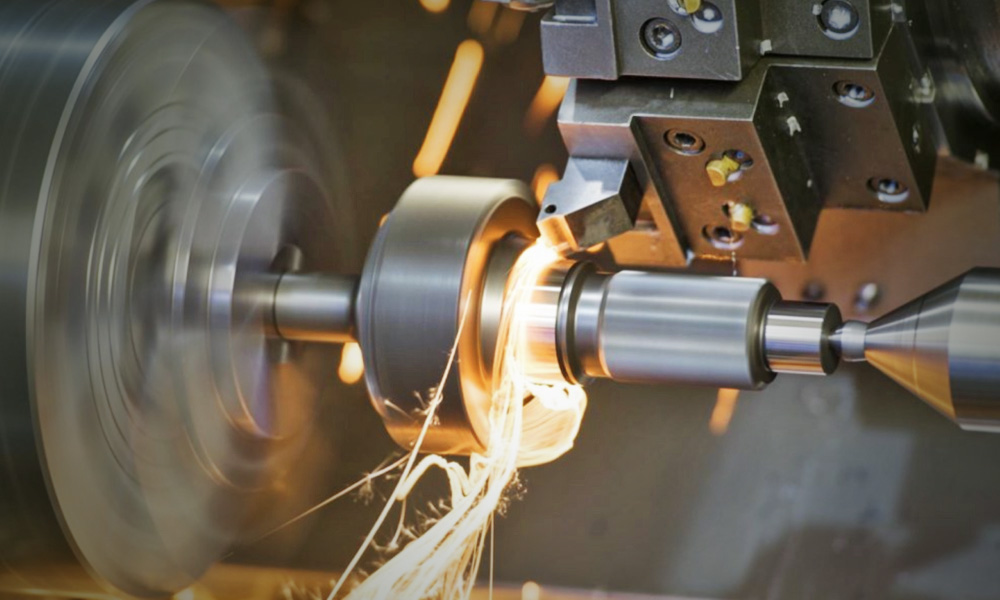

1. Vibration and Chatter Are Becoming the Norm

Occasional vibration happens. Persistent chatter does not.

If operators are regularly fighting vibration, it’s often a sign that something upstream needs attention. Common causes include:

- Tool overhang that’s longer than necessary

- Worn spindle bearings or machine components

- Tooling that no longer matches the material or operation

- Speeds and feeds that haven’t been revisited in years

When chatter becomes “expected,” surface finish suffers and tool life drops fast.

Refresh tip: Re-evaluate tooling selection, tool length, and cutting parameters – especially for repeat jobs that haven’t been optimized in a while.

2. Surface Finish Is Inconsistent or Declining

When parts start leaving the machine with variable finishes, it’s usually not a coincidence.

Finish issues often point to:

- Dull or mismatched tooling

- Heat buildup during cutting

- Inconsistent feeds or chip evacuation

- Small changes in setup that weren’t documented

If finishing passes require extra handwork to meet specs, your process is already costing more than it should.

Refresh tip: Look at finish quality over multiple runs. If operators are compensating with extra passes or polishing, it’s time to dial in the process – not the workaround.

3. Tool Wear Is Accelerating

If tools seem to be wearing out faster than expected – or unpredictably – it’s a red flag.

Increased tool wear can come from:

- Excessive heat

- Poor chip control

- Outdated cutting strategies

- Materials behaving differently than expected

Rising tooling costs often show up quietly on the balance sheet, long before anyone calls it a problem.

Refresh tip: Track tool life on key jobs. If replacement intervals are shortening, investigate cutting conditions and material handling rather than just ordering more tools.

4. Operators Rely on “Tricks” to Get Parts Out the Door

Experienced operators are great at making things work – but when success depends on personal tricks instead of documented processes, consistency suffers.

Common signs include:

- Manual feed overrides used on every cycle

- Extra pauses between operations

- Unofficial adjustments that aren’t written down

- Only one person knowing how to run a job correctly

These workarounds mask deeper issues and make training and scaling much harder.

Refresh tip: Ask operators what they’ve had to “work around” lately. Their answers often point directly to what needs fixing.

5. Rework and Scrap Are Slowly Increasing

A small uptick in rework doesn’t always trigger alarms – but over time, it adds up.

Rising rework can be caused by:

- Process drift

- Inconsistent setups

- Worn fixtures or tooling

- Changes in material batches

If inspections are catching more issues than they used to, the process may no longer be as stable as you think.

Refresh tip: Review rework trends over the last 6-12 months. Even modest increases are worth investigating before they become expensive.

When to Step Back and Re-Evaluate

A process refresh doesn’t always mean new machines or major investments. Often, it’s about revisiting fundamentals:

- Are speeds, feeds, and tooling still appropriate?

- Is the setup documented and repeatable?

- Are operators fighting the process – or working with it?

- Is heat, vibration, or wear limiting performance?

Taking time to reassess these areas can lead to better part quality, longer tool life, and a smoother shop floor.

Sometimes, the biggest gains come from small adjustments – once you know where to look.